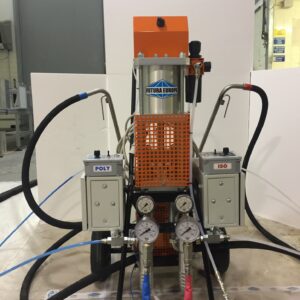

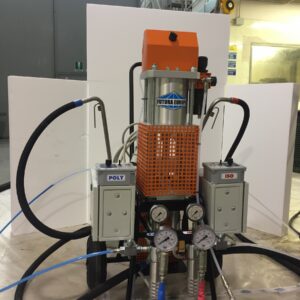

Machine for polyurethane and polyurea spray AM20

- Simple and fast application

- Durable and long-lasting

- Several options for decorative finishes

Low and high pressure capabilities, ideal for precise injection/spray jobs

This small and handy polyurea and polyurethane spray machine is designed to carry out small injection or spray jobs and can be used both at high and low pressure. Thanks to its features, this system is perfect for small and/or new applicators, restorers, general contractors, and manufacturing companies looking for the high performance of polyurea without the disadvantages of a high-pressure spray system, which are typically bulkier and more expensive.

In particular, the Futura AM20 spray machine for polyurea and polyurethane allows quick and easy civil and industrial flooring thanks to its special resin and polyurea systems; it can be equipped in low pressure (without heating) with the use of the BP2 gun (simpler, with disposable mixers) or with the FT3 trigger gun (classic for polyurea). The spray system is therefore extremely economical and practical.

Technical details

The resin and polyurea flooring that can be obtained with spray application is characterized by:

- Fast application and drying times – spray application is much faster than roller application (no mixing, no risk of uneven application) and the flooring will be walkable in just 6 hours.

- Self-levelling: the spray application allows to obtain a smooth and defect-free surface with minimal thickness.

- Advanced hybrid technology that retains color and shine.

- Can also be applied at low temperatures and in the presence of humidity

- Excellent abrasion and impact resistance.

- Excellent resistance to UV rays and maintenance of gloss.

- Highly resistant to oils and major chemicals.

- Available in a wide variety of colors.

- Possibility to add Quartz or other parts to obtain decorative finishes with granite effect or non-slip finishes.

- Environmentally friendly – contains no volatile parts.

- Safety valve

- High-precision pumping system that guarantees the correct mixing ratio throughout the entire processing time

- Moist-out system for closing pipes that avoids contamination of materials with external humidity

- Spray gun BP2

- Optional heating system with the possibility of setting different temperatures for isocyanate and polyol

- Thermometers that show the actual temperature of the material in the pipes

- Fast recirculation system, allows you to clean the isocyanated part quickly and easily

- In-line material filters

- Adaptable draft tubes for 20 lt and 200 lt drums complete with filters

- Showrooms & Shops

- Industrial Kitchens

- Restaurants & Bars

- Covered and uncovered parking lots

- Aircraft hangars

- Garages and access roads

- Laboratories, Hospitals, and Clinics

- Pharmaceutical industry facilities

- Food industries

- Manufacturing

- Office flooring