Polyurea is a type of liquid and very elastic membrane, ideal for waterproofing new or existing surfaces. Specifically, it is a special resin that allows us to solve the most common problems related to water infiltration, since it is able to form a homogeneous and impermeable coating over the entire treated surface, guaranteeing its tightness.

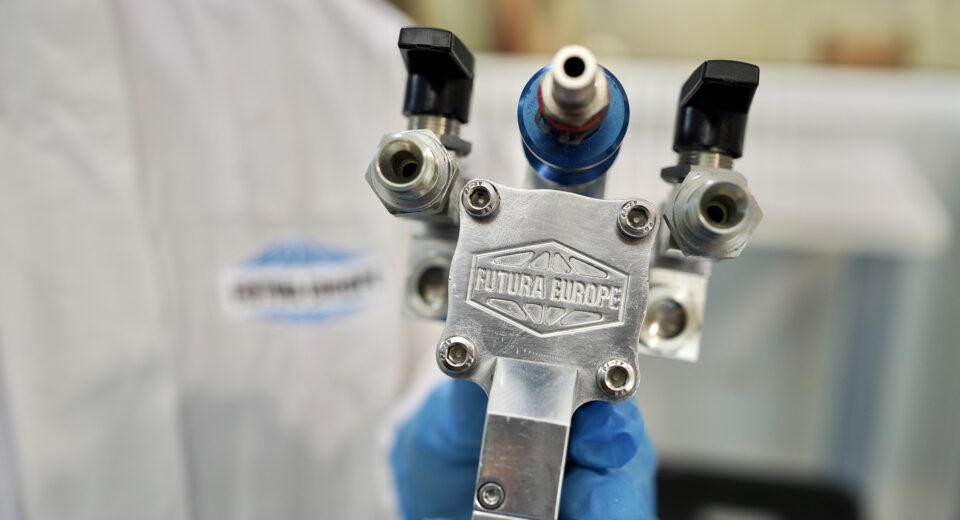

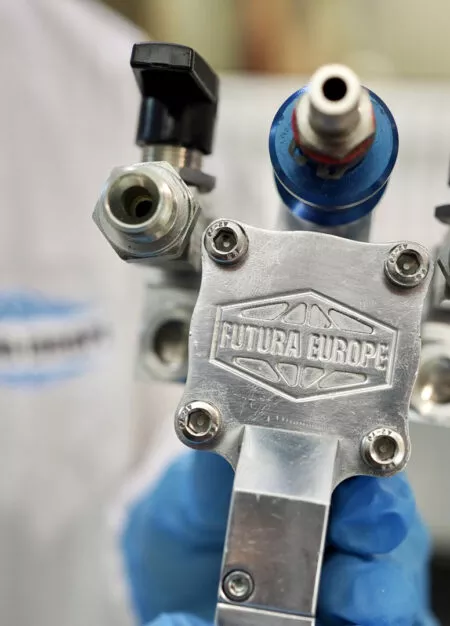

Polyurea can be applied by spraying, cold, casting, and blowing by sprayers, coating machines, roller machines (cold or manual polyureas), at both high and low pressure.